Thermal management has always been a major concern in the design of high frequency, high power electronic devices. For example, historically, in many power amplifier designs, the vast majority of the power that needs to be dissipated is from the high power field effect transistors, or FET's, themselves. In these cases, the high power dissipation often requires direct attachment of the FET's to a heat sink of some type. Heat sinks have become almost essential to modern central processing units and other electronic devices.

Ideally, heat sinks are made from a good thermal conductor such as silver, gold, copper or aluminum alloy. Copper and aluminum are among the most frequently used materials for this purpose with electronic devices. In addition, recently, synthetic diamond cooling sinks have been developed to provide better cooling. Further, some heat sinks are constructed of more than one material with desirable features, such as phase change materials. Such materials can store a great deal of energy due to their heat of fusion. However, while many of these materials provide heat sink features, they do not address other needs of the device, such as electrical insulation. This article will highlight those needs and how new materials deal with those requirements.

Applications Overview

Before discussing new developments in materials for thermal management, an overview of electronics applications and thermal management will be given. Currently, there are four general categories of electronic applications that require thermal management such as provided by heat sinks and other approaches. They can be broadly classified as (1) medical electronics (2) consumer electronics (3) automotive electronics and (4) aerospace and defense electronics. Each of these categories has unique requirements in terms of thermal management. A brief discussion of those various needs will now be presented.

In the area of medical electronics, from imaging equipment to surgical instruments and automated immunoassays, more power means more heat, generally in a small space. Further, as greater demands for precision and reliability are placed on medical equipment, thermal control becomes more critical. To address that concern, medical equipment designers are using passive thermal control systems that include heat pipes and vapor chambers. Such devices offer high reliability, design flexibility, manageable cost, and quiet operation.

The consumer electronics field is being driven by the need for smaller, faster and lighter products. That need has put considerable demands on the thermal management of microelectronics. This area offers potential opportunities for materials-enabled innovation. Materials for electronics such as tablets and smart phones are moving to encompass the entire body of the smart phone or tablet, making heat dissipation more effective. This will likely push the boundaries in new materials where aesthetics such as color and texture will become important features for adoption. Thermally conductive polymers are seeing an increase in this segment of the market.

Electronics in automobiles has become more and more sophisticated and power consumption only seems to increase. In recent years, the proliferation of electronic hybrid cars has created new cooling problems with electronics that control large amounts of current. For example, in automobiles like the Toyota Prius, cooling of the battery pack is necessary to keep the temperatures of all of the modules as uniform as possible. This maximizes the performance and the life of the battery. Unique materials solutions may offer opportunities to address these issues.

Aircraft thermal management is becoming increasingly important to the safe design and operation of commercial and military aircraft due to the growing heat loads from expanded avionic functionality, more electrical systems architectures, and the greater temperature sensitivity of composite material systems compared to traditional metallic designs. Military aircraft designers face the additional challenges of removing the waste heat from advanced weapon systems. Examples of components that are sensitive to thermal fluctuations are heat shields, anti-icing systems and propulsion systems. Presently, these needs are typically addressed through the use of air exchangers or some type of fan assembly.

Thus, of the four applications that have been discussed, the two areas for which new materials are of high priority are automobile and consumer electronics. Of these, consumer electronics appears to be the most needing of the new technologies. Attention will now be turned to current requirements and how those can be met by new materials.

Market Requirements

Until recently, metal-based systems have been the primary material solution of choice. Aluminum was primarily selected for various light-weight thermal management systems. However, these systems are becoming more expensive based on raw material price increases that have been observed over the past few years. In that regard, plastics offer suitable performance for many of the thermal management applications that are being developed.

In order to gain insight into developing needs, a recent SpecialChem survey asked respondents about material requirements for thermal management applications. The results of the survey were that thermal management goes beyond thermal conductivity alone. Specifically, electrical insulation and color freedom were valued as other features beyond thermal conductivity. In addition, the following percentage of the respondents voted for the various options:

| Physical Properties | Best In Class | Well Balanced | Cost Option |

| Electrically Insulating Plastic | Yes | Yes | No |

| Color/Colorability | White | White | Black |

| Resin + Filler Compound Price ($/100 cc) | 3,5 | 3 | 1 |

| Tensile Strength (MPa) | 100 | 65 | 65 |

| Impact Strength (J/m) | 80 | 35 | 35 |

| % of votes | 27% | 49% | 24% |

Table 1: Results of Survey on Thermal Management Materials

(based on 77 feedbacks)

|

From these results, it can be seen that a well-balanced formulation is the choice of about one-half of the respondents. In this context, a well-balanced formulation is described as one that provides not only thermal conductivity but also other features such as color. It should be noted that the cost option gathered the lowest percentage in the survey.

Thermally Conductive Plastics

In order to address present needs, thermally conductive plastics are made through the incorporation of high thermal conductivity fillers into the thermoplastic polymer matrix. Examples of common conductive fillers that are used are graphite, expanded graphite and carbon fibers. But, the use of these materials results in the final composite material being black and electrically conductive. As already stated, this is undesirable for consumer electronics applications such as smartphones. On the other hand,

boron nitride is a synthetic ceramic that is both an excellent conductor of heat and a dielectric material. Recently,

Momentive Performance Materials has developed

Boron Nitride fillers enabling composite to reach acceptable thermal and electrical properties.

There are other ceramic materials, such as alumina, aluminum nitride and silica that show similar characteristics but

boron nitride has the highest thermal conductivity of any of these materials. Table 2 provides a comparison of some properties of

boron nitride to other competing fillers.

| Property | BN | Al2O3 | AlN | SiO2 |

| Thermal Conductivity (W/m/K) | 300 | 30 | 260 | 1.3 |

| Dielectric Constant | 2.28 | 3.98 | 3.26 | 2.20 |

| Mohs hardness | <2 | >9 | ~ 7 | ~ 6.5 |

Table 2: Comparison of Boron Nitride to Other Fillers

|

As can be seen from this Table,

boron nitride offers both very high thermal conductivity values as well as a low dielectric constant. In addition, due to its softness, it can be readily compounded into many polymers with limited wear on the processing equipment.

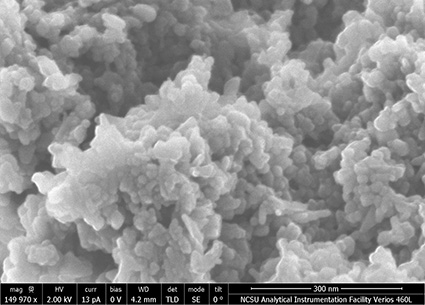

Momentive Performance Materials' New Grade of Boron Nitride

Momentive Performance Materials has recently developed a new grade of

boron nitride, designated

CFX 600, which provides enhanced thermal conductivity while at the same time providing electrical insulation in a wide variety of thermoplastic resins. It is a surface treated version of

boron nitride that allows for the attainment of high thermal conductivity and improved physical properties at lower loading levels than are commonly used. Specifically,

CFX 600 can provide up to 20% enhancement in thermal conductivity while potentially also providing improvements in mechanical properties compared to untreated

boron nitride powder at the same loading level.

This is just one example of a material development for thermal management that is focused on the growing needs of applications like consumer electronics. Those needs are clearly pointing out the requirement for more than simply thermal conductivity. Instead, materials solutions are being sought that provide a balance of properties in the final composite material. As these developing applications continue to stress the need for faster electronics, it is expected that materials developments will need to continue to address those needs.

Source: Special4polymers

For more details contact : innovative_growth@yahoo.co.in